Milling

|

|

|

|

|

Large Scale

3 Ton per hour (75 tons per day) and larger capacities up to 240+ tons per day in respect of maize and wheat mills is developed by ABC Hansen Africa in collaboration with such world class manufacturers as Imas from Turkey, United Milling Systems, Engsko and Skiold of Denmark, AGI, Sweet Manufacturing and Global Industries of the USA, Dynamic Generale of Italy and other renowned manufacturers.

In the case of maize mills, the Sub Sahara region has specific requirements, not nearly consistent for the region, for maize meal where it is often staple diet. In some Central and West African countries casava may form the main staple while maize would still be an important source of carbo hydrates.

In the pre-1990's maize meal was standardized into three distinct qualities by the then South African Maize Board who subsidized maize meal and had to ensure millers. The main two qualities were briefly defined as follows:

| Super Maize Meal | Special Maize meal | |

|---|---|---|

| Fat | Less than 2% | 2% min, 3% max |

| Fibre | 0.8% max | 1.2% max |

| Particle size | 90% <1,400my | 90% > 300my |

These qualities form a basis for maize meal throughout the Southern and East African region with major exceptions. The low fat content is achieved by de-germinating maize. In the case of grits used for beer, the fat content becomes even more important.

In some markets, while low fat content maize is desired, a finer particle size is preferred. This usually stems from a region where large scale roller mills ceased to function due to for instance conflict or economic factors, and where hammer milled meal formed the basis of the staple diet and to which the market became accustomed.

Inversely some markets prefer a coarser degerminated meal.

In all cases, meal is preferred with a longer shelf life which is obtained by removed as much of the germ as possible. A lower fibre content is also desired.

The ABC Hansen Africa maize milling systems keep all these factors in mind and design it accordingly.

In the case of large scale wheat milling, ABC Hansen Africa has not only its own expertise, but also that of its global partners at its disposal in the design of large scale milling systems for Africa.

Some equipment used in these systems are shown.

Medium Scale

Maize and wheat milling systems:

1,000kg to 2,500kg per hour systems are the result of ABC Hansen Africa's own manufacture and design. This excludes grain storage systems which are still imported but includes cleaners, aspirators, dampeners, conditioning, screw-, bucket, chain- and air conveyors, compact roller mills, mini plan sifters and bagging systems.

Systems are designed for maximum two to three milling lines as anything more becomes vastly inefficient both in operational terms and in maintenance cost.

A 1.2 - 1.5 ton per hour de-germinator and 4 break compact roller milling system form the heart of its maize milling program and is manufactured by ABC Hansen Africa at its Pretoria factory as well as all other items in such milling systems.

In the case of medium scale wheat mills, ABC Hansen's grain polisher which acts as intensive scourer, togther with its compact four stage roller mills and imported Danish stone mills, forms the basis of these milling systems and provides wheat flour of good commercial quality.

In the case of stoneground systems, roller mills are not used in these systems and a series of stone mills, preceded by grain polishers, are used. This does not provide white low ash flour of course but provides flour of high baking quality and of exceptional taste for the health conscious.

Medium scale systems for milling spelt and other special grains are designed to the buyers specifications and have been exported into Scandinavia while many commercial wheat mills were erected in different markets.

Augers Auger Filler SG75 Auger Filler SG60 Bran Finisher Bagging Bagging System on Frame SCBAG Cleaner Quail II: Eccentric type 2-3 T/H Cleaner Quail I: Eccentric type 0.5 - 1.5 T/H Dampener Degerminator 1500 Degerminator 3000 Francolin cleaner: Vibration Type Hurricane Roller Mills MRH500 MRH500TRIP Hurricane Roller Mill 3 Stage Moisture Tester SuperPro Moisture Tester SuperPro POLIS01 Grain Polisher Rotary Sifter Rotary Valve SIPC Mini Plansifter SIPC Mini Plansifter Stone Mill, Horizontal Vitamin Doser

Small Scale & Specialized Equipment Lines

200kg to 500kg per hour systems are designed and installed from its own manufacturing program in Pretoria. These systems include spice grinding systems, peanut butter plants, special grain milling plants and is effected by various stone mills, roller mills, plate mills, hammer mills and with various sifters such as mini plan sifters, turbo sifters and rotary sifters. Systems are preceded by cleaners, aspirators and other equipment as may be required such as small grain polishers, crushers, dampeners and conditioning systems.

Hippo Hammer Mills

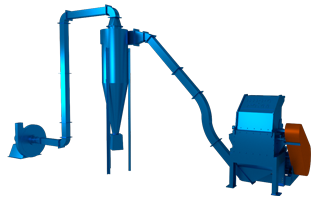

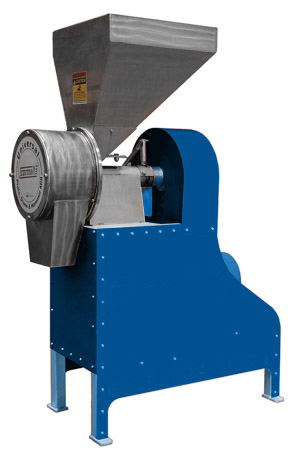

The heavy duty Hippo range of hammer mills are designed for industrial or commercial use where the mill operates for 24 hours a day and where it grinds all kinds of products with motor capacity as high as 110kW and as low as 2.2kW.All mills may be fitted with diesel engines or with PTO 3 point linkage.

Fans and cyclones with delivery spouting are ordered as standard equipment. Negative pressure suction machines are available on special order.

Larger mills (L63 and Mammoth) are supplied with separate negative suction air extraction system to include high pressure fans at 11 – 18kW with cyclone and spouting and rotary valves.

All indicative capacities are specified for milling maize at 12% moisture with a 1.6mm aperture in the screen.

Datasheet: MH47 FM Hippo 47 with fan

Datasheet: MH63 – Hippo L63 Hammer Mill

Datasheet: MHM Hippo Mammoth Hammer Mill

Containerized Maize Mill

Containerized Maize Mill

- Compact

- Includes cleaning system to remove all foreign material from grain before milling

- Conditioning of grain before milling for better quality

- De-germinator to separate bran and maize germ meal from samp.

- Plate mill OR Hurricane Roller mill or Hippo Hammer mill for quality maize meal with low percentage powder.

- Sifter to grade maize meal for high quality end product.

- Also ideal for sorghum.

- No installation costs at site required.

- Electrical system included, just plug into 3 phase power source.

- Optionally a diesel generator may be included.

- Special designs for one diesel drive on entire system.

- A Grain intake and storage system in containers above the milling container can be installed.

- Ideal for moving the milling system when required to do so and where no infrastructure exists.

Vertical & Horizontal Stone mills

Horizontal Stone Mill

Vertical Stone Mill

Datasheet: MSV Vertical StoneMill

The range of vertical and horizontal stone mills manufactured since 1925 in Denmark provides excellent milling quality.

Diamond 300 and 500mm mills and Farmers Favorite 600 and 950mm stone mills are standard items. Stone mills are ideal for the milling of spices, because of the low milling temperature, thus preventing discoloration and loss of flavor, and its ability to grind the product extremely fine. Many varied applications requiring fine milling with low oil and moisture content is routinely supplied, from macadamia nut shells to starch.

Stone milling of various grains are considered healthier than metal contaminated roller milling. As special health mills horizontal stone mills are routinely supplied with stone scourers and sifters. Very good quality fine flour can be obtained. Spelt (an ancient Bronze Age grain species related to wheat) milling in Europe is entirely done with stone milling systems.

The Plate Mill

A Plate Mill Datasheet: MPU Plate mill

The amazing plate mill provides solutions to many difficult milling applications such as for oily and wet products like peanut and other nut butter, full fat extruded soy beans, sugar, coffee, spices as well as dry and wet milling of grain.

Capacities depend on application and the size of the motor installed ( between 2.2kW single phase and 11 kW three phase motors are used) and would vary between 120kg/hr for peanut butter and 1,000kg per hour for sorghum or maize.

Wet milling of maize – used in making Mexican tortillas – can very effectively be done with a plate mill.

Sugar is milled into castor and icing sugar with a plate mill. Other products with high sucrose content such as the seeds of the prosopis tree has been effectively milled.

When used for processing human food, plate mills are supplied in stainless steel and with chromed parts.

ABC Hansen Africa also supplies DISC MILLS from its Danish associate companies, Engsko and United Milling Systems. Disc mills are high capacity mills used primarily in the feed industry and in industries where a low degree of pulverisation of product is required and a more even particle size is desired.

U.S. customers can order the ABC Hansen Universal Disc Mill Plate Grinder from Pleasant Hill Grain, the U.S. importer.

The Universal Mill

Datasheet: MPUU UNIVERSAL MILL

Without changing pulleys, a simple frequency inverter may be used to change the required speed of operation for the various applications.

The plate mill is used for grinding grains and wet and oily products. The hammer mill is used for milling herbs or other coarse / large particle, non free flowing material.

The stone mill is used for fine milling of all the above products other than wet and oily products.

U.S. customers can order the ABC Hansen Universal Disc Mill Plate Grinder from Pleasant Hill Grain, the U.S. importer. Read more...

Datasheet: CLD Destoner

Datasheet: ELCPXPART Electric Switchgear Cable

Datasheet: MED DIESEL ENGINE JD

Datasheet: MSHELL Maize Sheller

Datasheet: MSH Horizontal Stone Mill

Datasheet: PSHELL Peanut Sheller

Datasheet: SHA Conditioning Hopper

Part of the ABC Africa Group of Companies

Scanwood

ScanwoodHippo Mills

Trailsaddles.co.za